Salt Spray and Salt Fog Testing

The salt spray test is a standardized test method used to check corrosion resistance of coated samples. Coatings provide corrosion resistance to metallic parts. Since coatings can provide a high corrosion resistance through the intended life of the part in use, it is necessary to check corrosion resistance by other means. Salt spray test is an accelerated corrosion test that produces a corrosive attack to the coated samples in order to predict its suitability in use as a protective finish. The appearance of corrosion products (oxides) is evaluated after a period of time. Test duration depends on the corrosion resistance of the coating; the more corrosion resistant the coating is, the longer the period in testing without showing signs of corrosion.

Commonly Used Standards

ASTM B117

Standard Practice for Operating Salt Spray (Fog) Apparatus

5100Z-SEO-0000

Auto Suspension Parts-Coating Quality Standards

5100Z-SGO-A000

Auto Suspension Parts-Coating Quality Standards on Iron-Zinc Alloy Coated Steel Sheet

AAMA 2605

Performance Requirements & Test Procedures for Superior Performing Organic Coatings on Aluminum Extrusions and Panels

ASTM G85

Standard Practice for Modified Salt Spray (Fog) Testing

Daimler Chrysler LP-463-PB-10-01

Salt Spray Test

Daimler Chrysler PF-9688

Electrical/Electronics (E/E) Devise Environmental and Durability Testing Specifications

DIN 50021

Salt Spray Testing

Ford 00.00EA-D11

Environmental Requirements-Non EMC Vehicle Electrical and Electronic Systems

Ford BI 103-01

Salt Spray Resistance Test for Painted Panels and Parts

GM4298P

Salt Spray Test

GMI 60206

Determination of Resistance to Corrosion of Automotive Components

Honda HES 6501

Salt Spray Test

Honda HES D2021

Corrosion Proof Coating Testing

Honda HES D6001-049A

General Test Methods for Plating

IEC 68-2-52

Environmental Testing-Test Kb-Salt Mist, Cyclic

ISO 7253

Salt Spray Corrosion Testing

ISO 9227

Corrosion Tests in Artificial Atmospheres-Salt Spray Tests

JIS H 8502

Methods of Corrosion Resistance Test for Metallic Coatings

JIS Z 2371

Methods of Salt Spray Testing

MIL-STD-202, Method 101

Salt Atmosphere (Corrosion)

MIL-STD-810, Method 509

Salt Fog

Nissan NES M0140

Salt Spray Testing

Renault D17 1058/--H

Neutral Salt Spray Test

SAE J1455

Environmental Practice for Electronic Equipment Design (Heavy-Duty Trucks)

SAE/USCAR-15

Specification for Testing Automotive Miniature Bulb Socket/Circuit Plate Assemblies

Toyota TSH1552G

Test Method of Salt Spray

Toyota TSH3128G

Anti-Corrosion Paints for Parts

Cyclic Corrosion

Cyclic corrosion testing is a more realistic way to perform salt spray tests.Actual environmental conditions usually include both wet and dry conditions, thus it makes sense to pattern accelerated laboratory tests after these natural cyclic conditions.

Commonly Used Standards

5100Z-SEO-0000

Auto Suspension Parts-Coating Quality Standards

5100Z-SGO-A000

Auto Suspension Parts-Coating Quality Standards on Iron-Zinc Alloy Coated Steel Sheet

Ford BI 123-03

Component Corrosion Test

Ford WSS-M2P177-B1 & B2

Paint Performance, Chassis, Moderate Visibility, B1-10 Cycle Resistance, B2-20 Cycle Resistance

GM9540P

Accelerated Corrosion Test

GMW14872

Cyclic Corrosion Lab Test

HES D6001-049A

General Test Methods for Plating

IEC 68-2-52

Environmental Testing-Test Kb-Salt Mist, Cyclic

JIS H 8502

Methods of Corrosion Resistance Test for Metallic Coatings

Nissan NES 28401NDS01

Basic Physicochemical Environmental Specification of Electronic Parts

Nissan 92111DS00

Corrosion Test Procedure for Assessing the Outer Surface Corrosion Resistance of Aluminum Heat Exchangers

Toyota TSH1555G

Test Method for Accelerated Corrosion Under Complex Environment

Toyota TSH3128G

Anti-Corrosion Paints for Parts

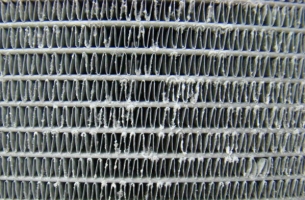

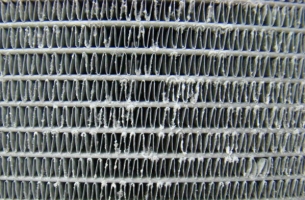

Acetic Seawater (SWAAT)and Copper Acetic Test (CASS)

The SWAAT test can be used to determine time to perforation primarily on aluminum alloy used to manufacture heat exchangers, and on plated parts. The CASS test is an accelerated corrosion test using copper chloride for some electrodeposits for anodic coatings on aluminum.

Commonly Used Standards

ASTM G85

A1, A2, A3, A4 & A5

ASTM B368

Standard Test Method for Copper Accelerated Acetic Acid Salt Spray (Fog) Testing (CASS Test)

DIN 50021

Salt Spray Testing

Ford BQ105-01

Copper Accelerated Acetic Acid Salt Spray Testing (CASS Test)

GM 4476P

CASS Test, Copper Accelerated Acetic Acid Salt Spray Test (Fog)

GME 60207

Determination of Resistance to Corrosion of Automotive Components by Copper Accelerated Acetic Acid Salt Spray (CASS)

GME 60213

Determination of Resistance to Corrosion of Aluminum Radiators by Sea Water Acetic Test (SWAAT)

HES D6001-049A

General Test Methods for Plating

ISO 6988

Kesternich Testing

ISO 9227

Corrosion Tests in Artificial Atmospheres-Salt Spray Tests

JIS H 8502

Methods of Corrosion Resistance Test for Metallic Coatings

Renault D17 3021/--B

Aluminum Tubes External Corrosion

Testing Services

Custom Testing

- Fixture Design

- Fixture Fabrication

- Custom Test Stands

- Prototype Testing Services

- Product Safety Testing Services

|

Electric Testing

- Dielectric Withstand

- Hi-Potential Testing

- Voltage Drop

- Contact Resistance

- Gate Leakage

- Insulation Integrity

- Dielectric Integrity

|

Corrosion Testing

- Salt Spray

- Salt Fog

- Cyclic Corrosion

- CASS

- SWAAT

- Combined Environment

|

Coating and Finish Durability

- Adhesion

- Impact Resistance

- Gravelometer

- Chemical Resistance

- Cyclic Corrosion

- Hardness

- Chipping Resistance

- Water Immersion

|

|

Learn More

|

Learn More

|

Learn More

|

Learn More

|

Abrasion/Wear

- Taber Abrasion

- RCA Wear Tester

- Resistance to Crocking

- Washability

- Pencil Hardness

- Finish Adhesion

|

Environmental Testing

- Thermal Cycle

- Powered Thermal Cycle

- High Temperature Storage

- Low Temperature Storage

- Humidity

- Temp-Humidity

- Autoclave

- Dust

- HAST

- Water Intrusion

- Ingress Protection

|

Mechanical Testing

- Flammability

- Solderability

- Drop

- Resistance to Solder Heat

- Destructibility

- Compression/Tension

- Conformal Coat Compatibility

- Resistance to Chemicals

- Resistance to Solvents

- FMVSS

- Package Testing

|

Pressure Testing

- Hydrostatic

- Burst Testing

- Proof Testing

- Leak Pressure

- Cyclic Pressure

- External Pressure

|

|

Learn More

|

Learn More

|

Learn More

|

Learn More

|